statische Seiten

The responsible handling of our environment and the sustainable use of its resources are just as central to our ETO DNA as the advancement and long-term development of our employees and the enhancement of their quality of life and that of all people.

As part of our corporate strategy, we are therefore committed to responsible corporate governance that is based on the three pillars of sustainability: environmental, governance, and social.

Through our actions, we support the Sustainable Development Goals (SDGs) of the United Nations.

Sustainability is practiced at ETO every day

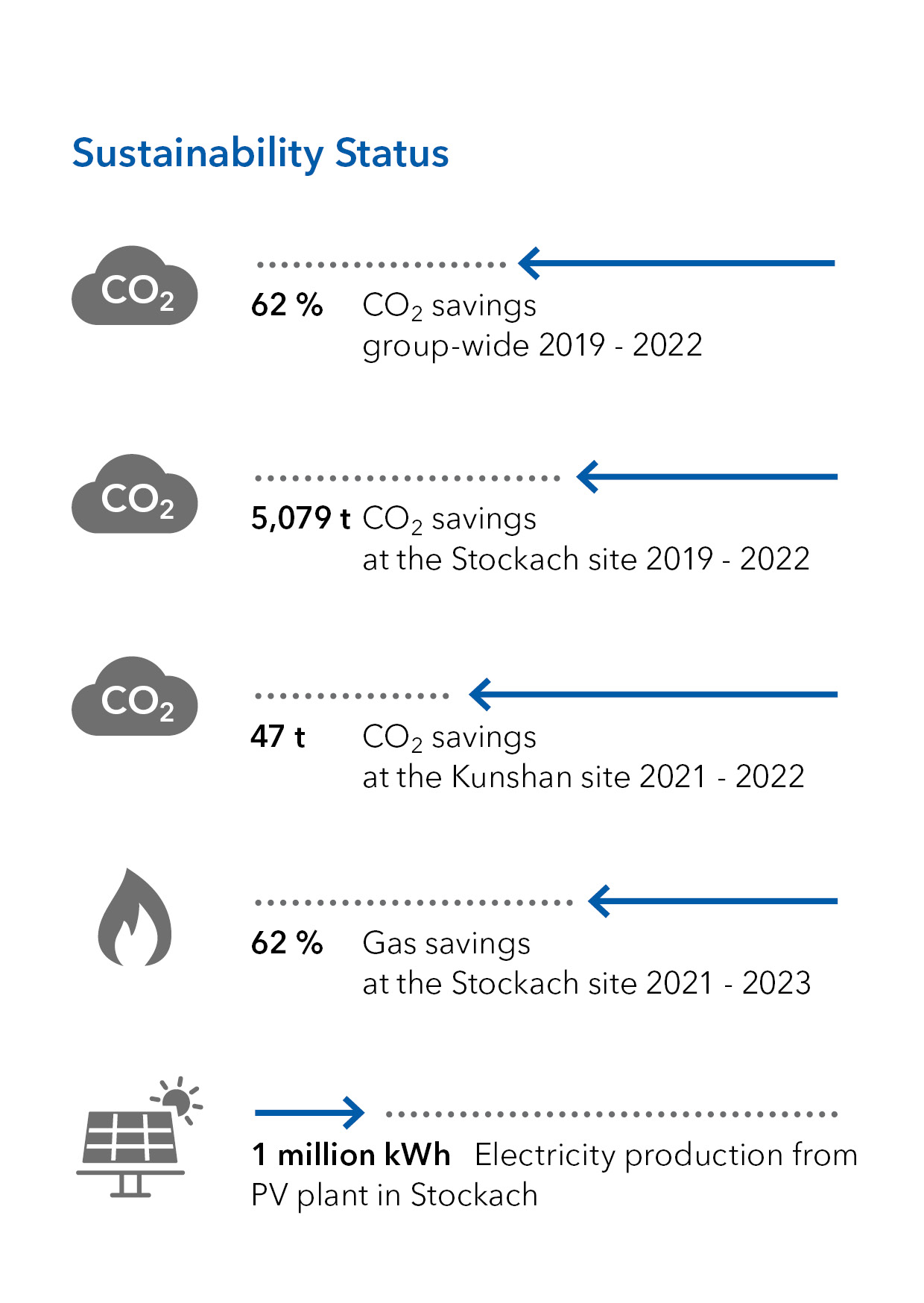

The photovoltaic plant at the Stockach site produces approximately 1 million kWh of electricity per year and saves 1,272 tons of CO2 emissions.

Sustainability is both a core competence and a vision

Sustainability and efficiency serve as essential guidelines concerning the functionality and performance of our products. As parts of drives, devices, or machines, ETO products ensure a reduction in energy or fuel consumption, leading to a decrease in CO2 emissions while enhancing performance at the same time. The use of raw materials and energy, as well as optimal recyclability, play a significant role in the development and manufacturing of our products.

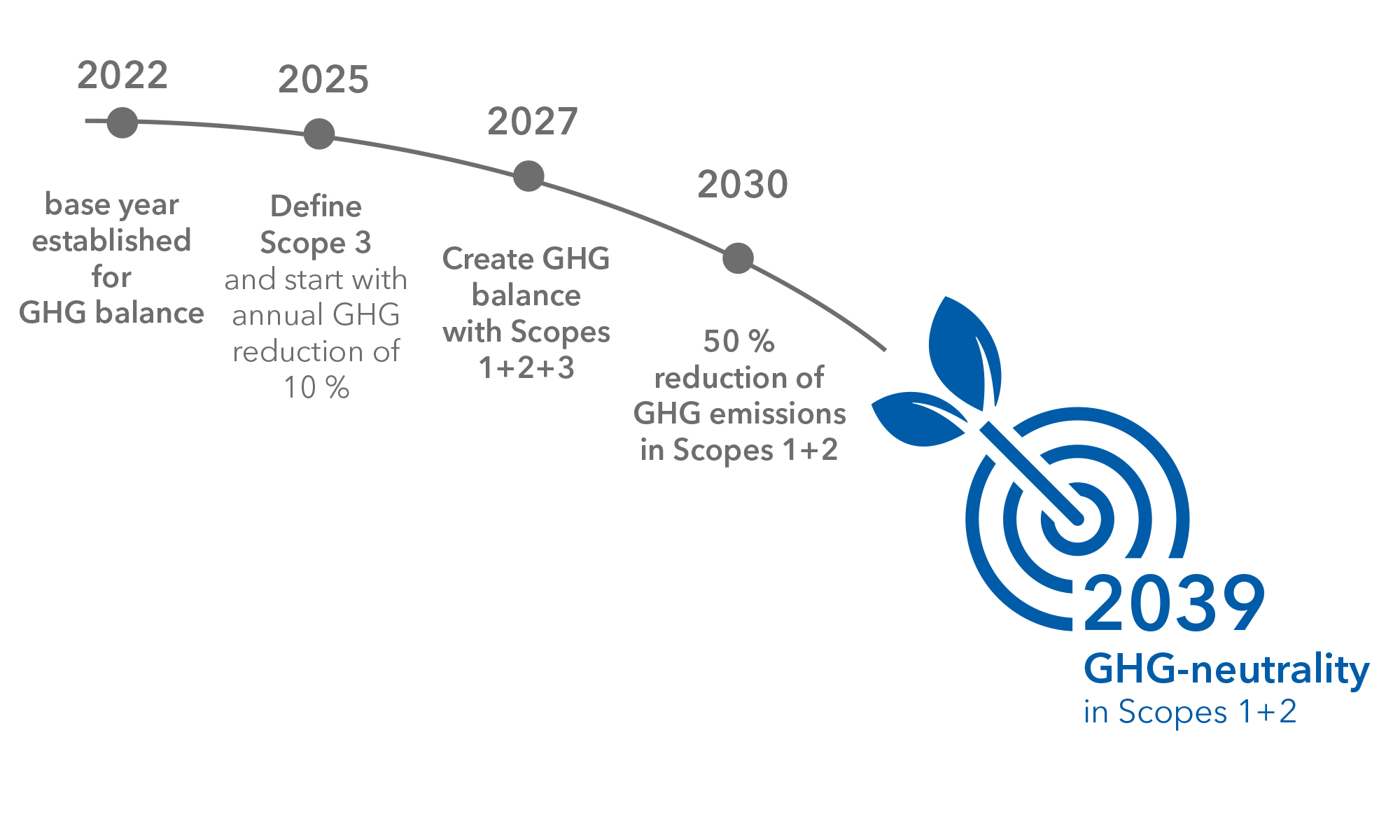

The ETO Sustainability Strategy outlines a defined course of action that is aligned with our vision of sustainably maintaining mobility for people and ensuring a livable planet by consistently enhancing safety, efficiency, and environmental compatibility through our products. All ETO sites have reached agreement on objective, measurable milestones to achieve this.

ETO’s vision of sustainability

We want to actively contribute to maintaining our planet as a livable, safe, and sustainable place. We do this for our employees and their families, as well as for future generations. To achieve this, we implement the highest environmental, energy, and occupational safety standards and commit ourselves to our social responsibility as a company.

The ETO mission for sustainability

We comply with all sustainability requirements, whether from our customers or from the legislator. We work safely – always and everywhere. We continuously reduce our emissions, taking into account our supply chains as well. We are improving our energy consumption through the introduction of state-of-the-art technology.

Sustainability is part of our development concept

Thanks to the measures implemented so far, ETO already outperforms the industry average in the sustainability rating of the automotive industry. However, this is no reason for us to relax, as our strategic goals are ambitious. The ETO GRUPPE aims to achieve climate neutrality at all its sites by 2039 and strives to completely avoid work-related accidents.

Our measures include reducing greenhouse gas emissions, the supply chain, the environment and energy, establishing high occupational safety standards at all ETO sites, and improving employee health.

One very fundamental objective is to raise the standards at all ETO sites to the highest level, despite the varying national legislations in some cases.

By 2030, energy consumption is to be reduced by 30 percent, and all ETO sites worldwide are to be certified according to ISO 45001, the international management system for occupational health and safety.

By 2030, energy consumption is to be reduced by 30 percent, and all ETO sites worldwide are to be certified according to ISO 45001, the international management system for occupational health and safety.

In addition, at all sites, a share of at least 90 percent of local suppliers and reusable packaging for all production material suppliers should be implemented.

Over the past few years, ETO has been carrying out intensive research in the area of the magnetic shape memory effect, significantly developing the material further and constructing actuators based on this. Today, ETO’s new MAGNETOSHAPE® is ready for use in initial series applications. Thanks to its unique advantages, the technology has the potential to replace electromagnetic and other actuator technologies in future.

Find out more about the one-of-a-kind MAGNETOSHAPE® technology and meet us in person at the Actuator in Bremen from 25 to 27 June, 2018.

The AeroMotive converter is a module that provides interfaces to LiDAR and camera systems for aviation applications. It forms the bridge between the automotive and avionics worlds. With the new converter, automotive components can be operated in helicopters. In the overall system, it contributes to increased safety by enabling the detection of obstacles such as power lines.

ETO has developed a coil and coretube module called NGx modular system in order to meet the individual requirements of our customers more quickly in the future.

The number of new components to be developed is low thanks to the modular system, so the production capacity is able to be freed up more quickly for new products.

In addition to optimised product development, the manufacturing of the products is also state-of-the-art thanks to new production concepts.

ETO in 30 seconds

The ETO GROUP companies impress with innovative actuators and sensors in the highest quality, and set standards for the latest vehicles and systems.

We create solutions for more safety, efficiency and ecology.

More than 100 million of our actuators, solenoid valves and sensors have been installed in commercial vehicles and passenger vehicles from all leading producers since 1980.

Our international representation and competitiveness as well as our high productivity help us to be market leaders in more and more new applications – for system suppliers and OEMs alike.

Completely in line with our vision: ETO: jointly innovative.

ETO in 30 seconds

At ETO, we want to ensure the sustainability of our planet. With innovation, strength, and passion, we develop and manufacture drive components, sensors, electronics, and software. These products regulate and control highly dynamic processes in the areas of mobility, vehicle technology and industrial plants. Our 2,000 employees worldwide work for the success of our customers. For more safety, efficiency, and environmental compatibility.

Group activities

Even outside of working hours, we enhance the ETO Team spirit with group activities, for example taking a trip to a climbing park, going rafting or enjoying our BBQ party in summer.

You will immediately become part of the ETO family during the introductory week. As well as important training, you will be able to explore the company and get to know one another at various team-building events.

Sports enthusiasts are welcome to join our running team or show off their skills in our very own football team.

The team behind the training

From left to right: Torben Müller – Trainer for electronics and mechatronics, Madeleine Krieg – Trainer for warehouse logistics, Robin Ritzi – Trainer for machining and industrial mechanics, Andreas Schulz – Trainer for electronics and mechatronics, Michael von Briel – Head of training, Simon Hensler – Trainer for machining and industrial mechanics, Benedikt Maroni – Trainer for technical product design, Anna Strigel – Trainer for industrial merchants.

Not pictured: Gregor Buckenmaier - Trainer for computer science system integration

Do you still have questions that need answering or queries about training?

Then get in touch with your contact partner:

Michael von Briel

Telephone: +49 7771 809-1209

The purchasing department of the ETO GRUPPE has dedicated itself to being a competent partner for all those involved in the value chain to deliver a significant and sustainable contribution to the company success of the ETO GRUPPE.

ETO’s global purchasing organisation is derived from this dedication.

Purchasing production materials is structured according to product groups and is carried out locally by the independently operating ETO sites. The job of the local purchasing organisation is to secure a constant flow of material with cost-efficient acquisition from authorised sources of supply that meet quality standards.

In doing so, central product group management guarantees a group-wide and national strategic alignment, which in particular includes the use of synergies at the individual ETO sites.

In the ETO development sites, the supplier is accompanied by a project purchaser, who supports the supplier as a central point of contact during the development phase through to series production. Here we integrate our target suppliers in the development at an early stage.

We see our target suppliers as strategic partners for joint and sustainable company success.

Be it in research, development, sales, production, IT or administration, ETO offers you diverse and exciting fields of activity – on an international scale!

You can find information on data protection in the context of your application here.